Challenges for Vegetable Factory

– Bearing the Future of Agriculture.

Outlook of Vitec Vegetable Factory

Restar Group is promoting to solve social problems through diversified business development and co-creation with our partners. One of these is the challenge of the Vitec Vegetable Factory which is running the one of the largest-scale vegetable factories in Japan.The business is also linked to concrete activities for the SDGs (Sustainable Development Goals). We talk about the business and the new style of vegetable production that is now being sought.

Stable supply, no pesticides, unaffected by various weather conditions or climate

– advantages of factory-made vegetables

The Vitec Vegetable Factory was established in 2015 to address social issues such as labor shortages due to the ageing of the farming workforce and the need for a stable supply of food, and to provide a solution to these problems by using electronics to work on a new way of producing vegetables. It was started in 2015 as a challenge for a new market of the food industry.

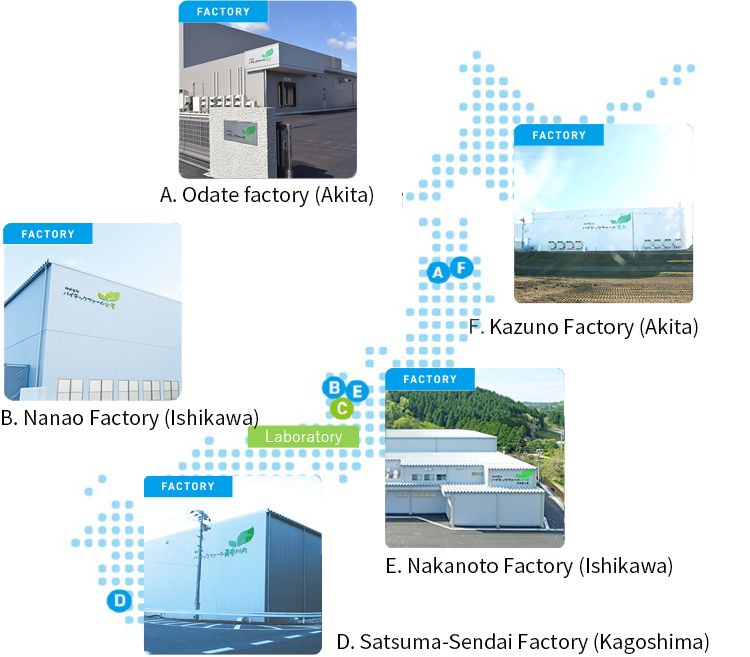

The first vegetable factory went into operation in 2016, and by 2018, we had five factories and one research and development facility in operation nationwide. We produce and sell leaf lettuce and some other vegetables and have achieved one of the largest supply scales for factory-made products in Japan.

Unlike "open field" cultivation, factory-made vegetables are grown in a "hydroponic" way, with LED and fluorescent lights.

There are many advantages to factory-made vegetables. Firstly, they are not affected by weather conditions or climate and can be produced consistently throughout a year, regardless of the season. Secondly, they can be harvested in a shorter period than that of open field cultivation, as they are grown in an optimized environment that provides the best lighting, temperature and nutrients for the vegetables, accelerating the growth speed. The completely closed production environment eliminates the need for agricultural chemicals and is therefore safer and more secure.

Wide range of product lineup from supermarkets (for retail use) to commercial use

Green leaf

Green leaf

Frill lettuce

Frill lettuce

Romaine lettuce

Romaine lettuce

Further spread of vegetable factories. Contributing to local community through new forms of agriculture

Looking at agriculture as a whole, stable food supplies and sustainable agriculture promotion are major issues in the SDGs(Sustainable Development Goals) which are attracting global attention. In order to cope with the food crisis, the vegetable factory business will be required to grow a wider variety of vegetables in the future.

We also want to contribute to the problems facing Japanese agriculture, such as the decline in the agricultural population due to the low birthrate and longevity, and the decline in food self-sufficiency rates. We are also planning to franchise our vegetable factories to be run by local people. We also aim to contribute to the revitalization of local employment through our factories.

Future of agriculture with electronics technology

In order to meet these challenges, we need to take on even more technological challenges. Since our establishment, we have been using electronics technology within the Group and working with various companies to establish mass production technology.

It is important to improve cultivation methods by researching suitable ways of growing vegetables in an artificial environment, rather than simply imitating open field cultivation for vegetable factories. Furthermore, our future goal is to create "new vegetables" that can only be grown in factories. Even today, technology has made it possible to produce vegetables that are like supplements with high nutritional value.

Our aim is to continue to innovate and constantly develop new markets by collaborating widely with companies, research institutions and local authorities in Japan and abroad.